BLOW MOULDING

BLOW MOULDING

As leaders in the industry, we specialize in designing and compounding high-performance thermoplastic materials tailored to your unique needs. From additive manufacturing to injection moulding, our progressive technologies ensure the delivery of top-quality products, setting new standards in versatility and durability.

As leaders in the industry, we specialize in designing and compounding high-performance thermoplastic materials tailored to your unique needs. From additive manufacturing to injection moulding, our progressive technologies ensure the delivery of top-quality products, setting new standards in versatility and durability.

Blow Moulding

is a common technique used to make hollow parts. Plastic is extruded as a parison into a hollow mould. Air is then blown in, forcing the material to inflate and form the shape of them mould. This is a common method for producing bottles.

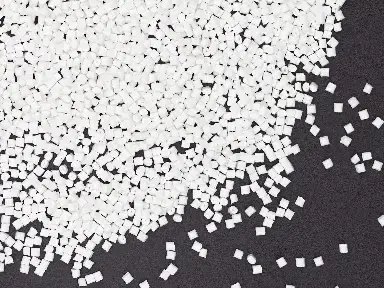

Innomerix offers a range of plastic compounds suitable for blow moulding. We specialise in the development of fibre reinforced thermoplastics, UV resistant compounds and monolayer barrier solutions. The result is light-weight products with excellent properties, to help meet your requirements

Blow Moulding

is a common technique used to make hollow parts. Plastic is extruded as a parison into a hollow mould. Air is then blown in, forcing the material to inflate and form the shape of them mould. This is a common method for producing bottles.

Innomerix offers a range of plastic compounds suitable for blow moulding. We specialise in the development of fibre reinforced thermoplastics, UV resistant compounds and monolayer barrier solutions. The result is light-weight products with excellent properties, to help meet your requirements